Iifilimu ezahlukeneyo zihlala zisetyenziswa kubomi bemihla ngemihla. Zenziwe ngantoni ezi filimu? Zithini iimpawu zokusebenza kwefilimu nganye? Oku kulandelayo yintshayelelo eneenkcukacha kwiifilimu zeplastiki ezisetyenziswa rhoqo kubomi bemihla ngemihla:

Ifilimu yeplastiki yifilimu eyenziwe nge-polyvinyl chloride, i-polyethylene, i-polypropylene, i-polystyrene kunye nezinye ii-resin, ezisetyenziswa rhoqo ekupakisheni, ekwakheni, nanjengomaleko wokugquma, njl.njl.

Ifilimu yeplastiki inokwahlulwa ibe

–Ifilimu yemizi-mveliso: ifilimu evuthuziweyo, ifilimu ekwikhalenda, ifilimu eyoluliweyo, ifilimu yabalingisi, njl.njl.;

– Ifilimu yeshedi yezolimo, ifilimu ye-mulch, njl.njl.;

–Iifilimu zokupakisha (kubandakanya iifilimu ezidityanisiweyo zokupakisha amayeza, iifilimu ezidityanisiweyo zokupakisha ukutya, njl.njl.).

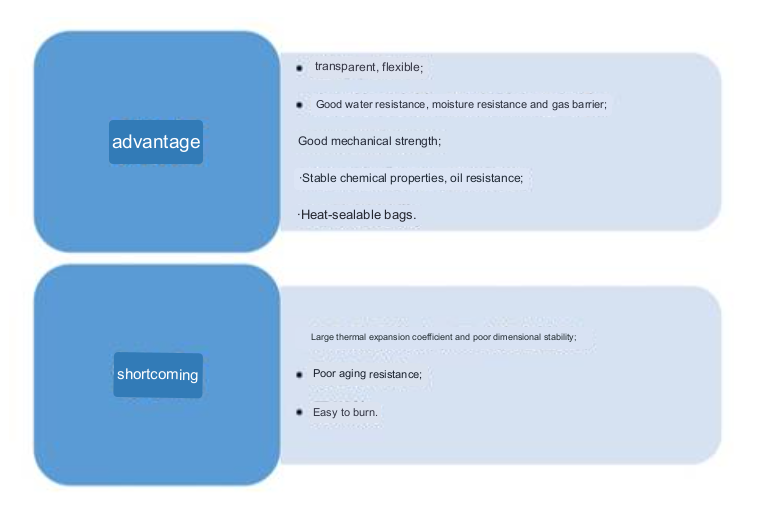

Iingenelo kunye nokungalungi kwefilimu yeplastiki:

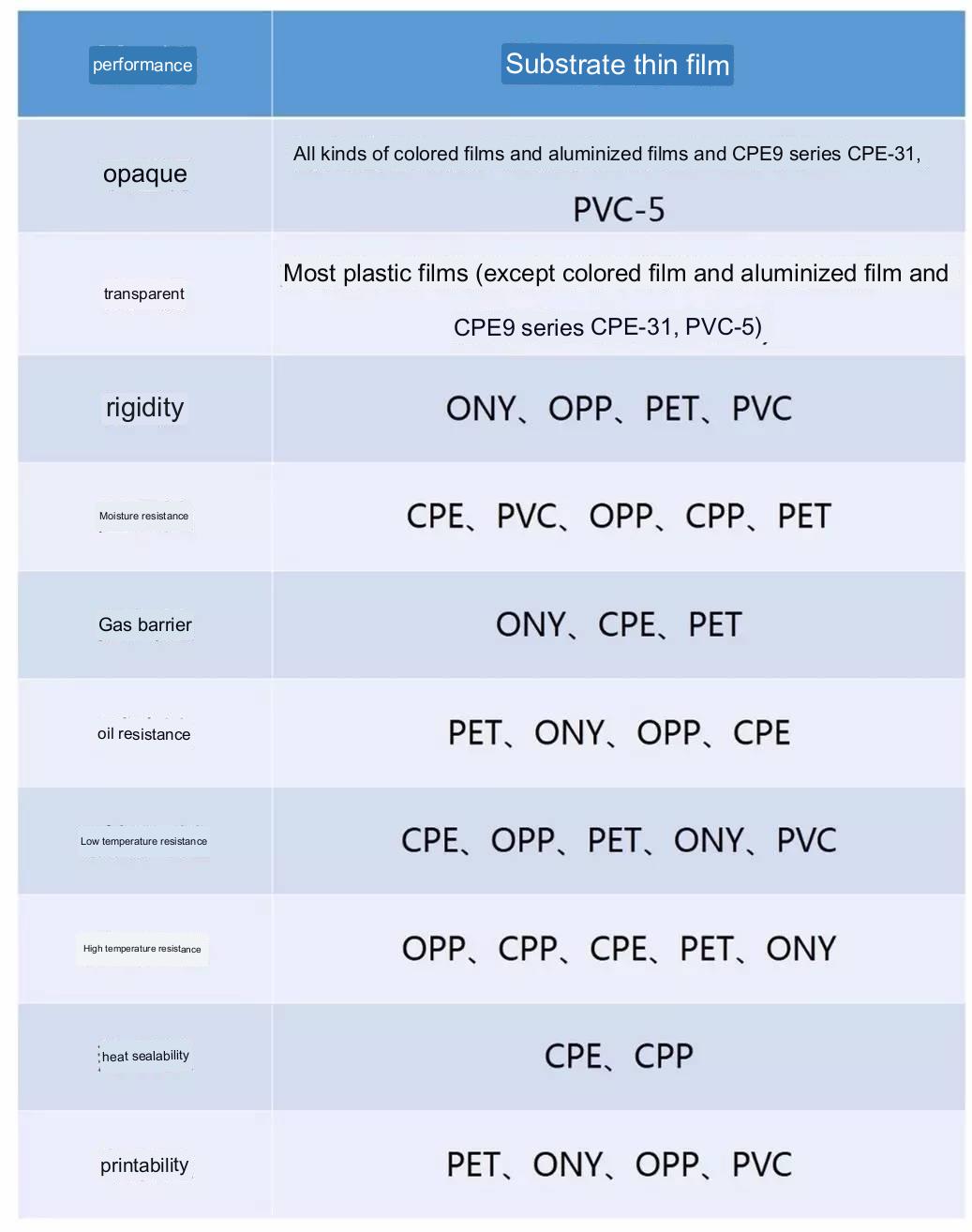

Iimpawu zokusebenza kweefilimu eziphambili zeplastiki:

Ifilimu yePolypropylene ejolise kabini (BOPP)

I-Polypropylene yi-thermoplastic resin eveliswa yi-polymerization ye-propylene. Izinto ze-Copolymer PP zinobushushu obuphantsi bokujika kobushushu (100°C), ukukhanya okuphantsi, ukukhanya okuphantsi, kunye nokuqina okuphantsi, kodwa zinamandla okujika angaphezulu, kwaye amandla okujika e-PP ayanda ngokunyuka komxholo we-ethylene. Ubushushu bokuthambisa be-Vicat be-PP yi-150°C. Ngenxa yezinga eliphezulu le-crystallinity, le nto inobunzima obuhle kakhulu bomphezulu kunye neempawu zokumelana nokukrwela. I-PP ayinazo iingxaki zokuqhekeka koxinzelelo lokusingqongileyo.

Ifilimu yepolypropylene ejongeka kabini (i-BOPP) sisixhobo sokupakisha esibonakalayo nesiguquguqukayo esaphuhliswa ngeminyaka yoo-1960. Isebenzisa umgca wemveliso okhethekileyo ukuxuba izinto eziluhlaza zepolypropylene kunye nezongezo ezisebenzayo, izinyibilikise kwaye zixove zibe ngamashiti, ize zolulwe zibe ziifilimu. Isetyenziswa kakhulu ekupakisheni ukutya, iilekese, iicuba, iti, ijusi, ubisi, amalaphu, njl.njl., kwaye inegama elithi "Packaging Queen". Ukongeza, ingasetyenziswa nasekulungiseleleni iimveliso ezisebenzayo ezinexabiso eliphezulu ezifana neemembrane zombane kunye neemembrane ezincinci, ngoko ke amathuba ophuhliso lweefilimu zeBOPP abanzi kakhulu.

Ifilimu ye-BOPP ayinazo nje kuphela iingenelo zoxinano oluphantsi, ukumelana nokugqwala okuhle kunye nokumelana nobushushu okuhle kwe-resin ye-PP, kodwa ikwanazo neepropati ezilungileyo zokukhanya, amandla aphezulu oomatshini kunye nemithombo etyebileyo yezinto eziluhlaza. Ifilimu ye-BOPP inokudityaniswa nezinye izinto ezineempawu ezikhethekileyo ukuphucula okanye ukuphucula ukusebenza. Izinto ezisetyenziswa rhoqo ziquka ifilimu ye-PE, ifilimu ye-salivating polypropylene (CPP), ifilimu ye-polyvinylidene chloride (PVDC), ifilimu ye-aluminium, njl.njl.

Ifilimu yePolyethylene enoxinano oluphantsi (LDPE)

Ifilimu yePolyethylene, oko kukuthi i-PE, ineempawu zokuxhathisa ukufuma kunye nokungafumani ukufuma okuphantsi.

I-polyethylene enoxinano oluphantsi (LPDE) yi-resin yokwenziwa efunyenwe yi-ethylene radical polymerization phantsi koxinzelelo oluphezulu, ngoko ke ikwabizwa ngokuba yi-"polyethylene enoxinano oluphezulu". I-LPDE yimolekyuli enamasebe anamasebe anobude obahlukeneyo kwikhonkco eliphambili, enamasebe angama-15 ukuya kuma-30 e-ethyl, butyl okanye amade kwi-athomu zekhabhoni ezili-1000 kwikhonkco eliphambili. Ngenxa yokuba ikhonkco le-molecular lineekhonkco ezinde nezimfutshane, imveliso inoxinano oluphantsi, ukuthamba, ukumelana nobushushu obuphantsi, ukumelana nempembelelo elungileyo, ukuzinza okuhle kweekhemikhali, kunye nokumelana ne-asidi ngokubanzi (ngaphandle kwee-asidi ezinamandla ze-oxidizing), i-Alkali, ukubola kwetyuwa, ineempawu ezilungileyo zokuthintela umbane. Ikhanya kwaye iyakhazimla, inozinzo oluhle lweekhemikhali, ukuvaleka kobushushu, ukumelana namanzi kunye nokufuma, ukumelana nokubanda, kwaye inokubiliswa. Ingxaki yayo ephambili kukuba ayinayo i-oxygen eyaneleyo.

Idla ngokusetyenziswa njengefilimu yomaleko wangaphakathi wezinto zokupakisha ezidityanisiweyo, kwaye ikwayeyona filimu yokupakisha yeplastiki esetyenziswa kakhulu nesetyenziswa kakhulu okwangoku, ibala ngaphezulu kwe-40% yokusetyenziswa kweefilimu zokupakisha zeplastiki. Kukho iintlobo ezininzi zeefilimu zokupakisha ze-polyethylene, kwaye ukusebenza kwazo kwahlukile. Ukusebenza kwefilimu yomaleko omnye kukodwa, kwaye ukusebenza kwefilimu edityanisiweyo kuyahambelana. Yinto ephambili yokupakisha ukutya. Okwesibini, ifilimu ye-polyethylene ikwasetyenziswa kwicandelo lobunjineli bokwakha, njenge-geomembrane. Isebenza njengengangeni manzi kubunjineli bokwakha kwaye inomoya ophantsi kakhulu. Ifilimu yezolimo isetyenziswa kwezolimo, enokwahlulwa ibe yifilimu yeshedi, ifilimu ye-mulch, ifilimu yesiciko esikrakra, ifilimu yokugcina eluhlaza njalo njalo.

Ifilimu yePolyester (PET)

Ifilimu yePolyester (PET), eyaziwa ngokuba yi-polyethylene terephthalate, yiplastiki yobunjineli ye-thermoplastic. Yinto eyenziwe ngefilimu eyenziwe ngamashiti amakhulu ngokuphuma aze asolulwe kabini. Ifilimu yePolyester ibonakaliswa ziimpawu ezintle zoomatshini, ukuqina okuphezulu, ubulukhuni kunye nokuqina, ukumelana nokubhoboza, ukumelana nokungqubana, ubushushu obuphezulu kunye nokumelana nobushushu obuphantsi, ukumelana neekhemikhali, ukumelana neoyile, ukuqina komoya kunye nokugcinwa kwevumba elimnandi. Yenye yezona substrates zefilimu ezidityanisiweyo ezihlala zihleli, kodwa ukumelana ne-corona akulunganga.

Ixabiso lefilimu ye-polyester liphezulu kakhulu, kwaye ubukhulu bayo ngokubanzi yi-0.12 mm. Ihlala isetyenziswa njengezinto zangaphandle zokupakisha ukutya, kwaye inokuprintwa kakuhle. Ukongeza, ifilimu ye-polyester idla ngokusetyenziswa njengezinto zokuprinta kunye nokupakisha ezifana nefilimu yokukhusela okusingqongileyo, ifilimu ye-PET, kunye nefilimu emhlophe enobisi, kwaye isetyenziswa kakhulu kumashishini afana neplastiki eqinisiweyo yefayibha yeglasi, izixhobo zokwakha, ukuprinta, kunye namayeza kunye nempilo.

Ifilimu yeplastiki yenylon (ONY)

Igama lekhemikhali le-nylon yi-polyamide (PA). Okwangoku, kukho iintlobo ezininzi ze-nylon eziveliswa kwimizi-mveliso, kwaye iintlobo eziphambili ezisetyenziselwa ukuvelisa iifilimu yi-nylon 6, i-nylon 12, i-nylon 66, njl. Ifilimu ye-nylon yifilimu eqinileyo kakhulu ecacileyo, i-gloss elungileyo, amandla aphezulu okutsalwa kunye namandla okutsalwa, kunye nokumelana okuhle nobushushu, ukumelana nokubanda, ukumelana neoyile kunye nokumelana nesinyibilikisi sendalo. Ukumelana okugqwesileyo kokuguguleka kunye nokubhoboza, iipropati ezithambileyo, ezintle kakhulu zokuthintela ioksijini, kodwa iipropati ezingezizo zokuthintela umphunga wamanzi, ukufunxwa komswakama ophezulu kunye nokungangeni komswakama, ukungatyi kakuhle kobushushu, okufanelekileyo ukupakisha izinto eziqinileyo, njengokutya okunamafutha, iimveliso zenyama, ukutya okuqhotsiweyo, ukutya okupakishwe nge-vacuum, ukutya okuphekiweyo ngomphunga, njl.

Ifilimu yePolypropylene eyenziwe ngeCast (CPP)

Ngokungafaniyo nenkqubo yefilimu ye-polypropylene ejongeka kabini (BOPP), ifilimu ye-cast polypropylene (CPP) yifilimu engasoluliyo, engajongekanga ngokuthe nkqo eveliswa yi-melt casting and quenching. Iphawulwa ngesantya sokuvelisa esikhawulezayo, imveliso ephezulu, ukucaca okuhle kwefilimu, ukukhanya, ukufana kobukhulu, kunye nokulinganisela okugqwesileyo kweempawu ezahlukeneyo. Ngenxa yokuba yifilimu ebekwe ngokuthe nkqo, umsebenzi wokulandelelana ofana nokuprinta kunye nokudibanisa kulula kakhulu. I-CPP isetyenziswa kakhulu ekupakisheni amalaphu, iintyatyambo, ukutya, kunye nezinto ezifunekayo zemihla ngemihla.

Ifilimu yeplastiki egqunywe nge-aluminium

Ifilimu e-aluminium ineempawu zefilimu yeplastiki kunye neempawu zesinyithi. Indima yokufakelwa kwe-aluminium kumphezulu wefilimu kukukhusela ukukhanya nokuthintela imisebe ye-ultraviolet, engagcini nje ngokwandisa ubomi beshelufu bomxholo, kodwa ikwaphucula ukukhanya kwefilimu. Ke ngoko, ifilimu e-aluminium isetyenziswa kakhulu kwiipakethe ezidityanisiweyo, ezisetyenziswa kakhulu kwiipakethe zokutya ezomileyo nezifumileyo ezifana neebhisikithi, kunye neepakethe zangaphandle zamayeza athile kunye nezinto zokuthambisa.

Ixesha lokuthumela: Julayi-19-2023