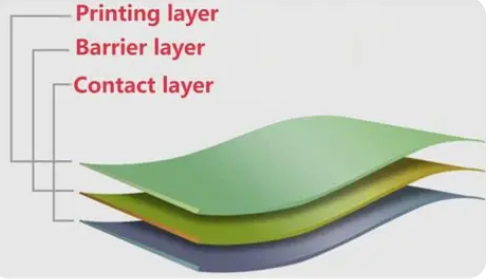

1. Packaging Materials. Structure And Characteristics:

(1) PET / ALU / PE, suitable for a variety of fruit juices and other beverages formal packaging bags, very good mechanical properties, suitable for heat sealing;

(2) PET / EVOH / PE, suitable for a variety of fruit juices and other beverages vertical bags, good barrier properties, good transparency;

(3) PET / ALU / OPA / PE, better than “PET / ALU / PE” drop resistance;

(4) PET / ALU / PET / PE, for a variety of non-concentrated beverages, tea and coffee and other beverages vertical packaging bags, better than the “PET / ALU / PE” mechanical properties (Note: ALU for aluminum foil, the same below).

Coffee is a traditional European product with a long history of packaging development. Nowadays, various composite structures are available to meet any storage and presentation requirements for coffee.

Printing method: gravure, up to 10 colors.

Packaging form: 3-side or 4-side seal, for vacuum or air-conditioned packaging of granules or powders. Packaging materials, structure and characteristics:

(1) PET / ALU / PE, suitable for vacuum or air-conditioned packaging bags

Commonly used for perishable food products that are kept for a long period of time and whose packaging is required to ensure a high level of freshness and product presentation.

Printing method: gravure printing, up to 10 colors.

Packaging form: three-sided packaging.

Packaging machines: horizontal and vertical packaging machines.

Packaging materials, structure and characteristics;

(1) PET/ PE, suitable for high speed packaging of fruits;

(2) PET/ MPET/PE, aluminized composite film with good visual effect, suitable for packaging of vegetables, jam and fresh meat;

2.Coffee Packaging Bags

(2) OPP/ALU/PE, suitable for vacuum or air-conditioning packaging bags, with very good mechanical resistance and good on-machine processing performance;

(3) PET / M / PE, suitable for vacuum or air-conditioned bags, without the use of aluminum foil barrier is quite high;

(4) Paper/PE/ALU/PE, suitable for single bag vacuum or air-conditioned packaging, easy to eat;

(5) OPA/ALU/PE, suitable for vacuum or air-conditioned packaging bags, with high barrier property and excellent mechanical resistance.

3.Meat Products Packaging Film

Meat packaging uses a wide range of composite materials to meet a variety of different preservation and packaging processing conditions. In addition to the traditional composite materials suitable for high temperature and pasteurization use, transparent, high barrier properties of the new structure is also being introduced, these structures are suitable for gas and vacuum packaging.

Printing method: gravure or flexo.

Packaging forms: preformed pouches (including pouches for ham packaging, three-sided flat-sealed pouches for cooked meat products), thermoformed rolled material (used as the bottom and lid of the tray).

Packaging machine: thermoforming machine

Packaging materials, structure and characteristics:

(1) OPA / ALU / PE, suitable for pasteurization, for ham packaging bags;

(2) PER/ALU/PET/PE, suitable for pasteurization, for cooked ham sterilization bags;

(3) PET / ALU / PET / PP, suitable for semi-finished products, cooked ham bags, can be sterilized at high temperature;

(4) PET/ALU/PE, suitable for meat slices packaging tray cover, etc;

(5) PA / EVOH / PE, can be potential molding, high barrier, suitable for ham slice vacuum packaging;

(6) PET / EVOH / PE, high barrier, suitable for ham vacuum packaging;

(7) PA / PE, can be potential molding, and product adhesion is very good, suitable for ham bags;

(8) PVE / EVOH / PE, can be potential molding, good stiffness, high barrier, suitable for air-conditioned packaging.

4.Frozen Food Packaging Bag

5. Fresh Jam Packaging Bag

Several air-conditioned packaging methods are often used in the packaging of such products, in which the composite structure should be adapted to heat treatment.

Printing method: gravure or flexographic printing.

Packaging form: thermoforming trays, bags.

Packaging machine: vertical bloom a filling a sealing (VFFS) packaging machine.

Packaging materials, structure and characteristics:

(1) PET/ PP, good mechanical properties, can be pasteurized, suitable for air-conditioned packaging and pasteurized tray closure lid, easy to tear;

(2) PET/EVOH/PE, high gas barrier, used for tray closure lids for air-conditioned packaging;

(3) PET/EVOH/PP, same as the previous one, but suitable for potential treatment;

(4) OPA / PE, has very good mechanical properties, suitable for air-conditioned packaging;

(5) OPA / PP, high transparency, suitable for heat treatment, suitable for air-conditioned packaging and pasteurization.

Post time: Jun-17-2025