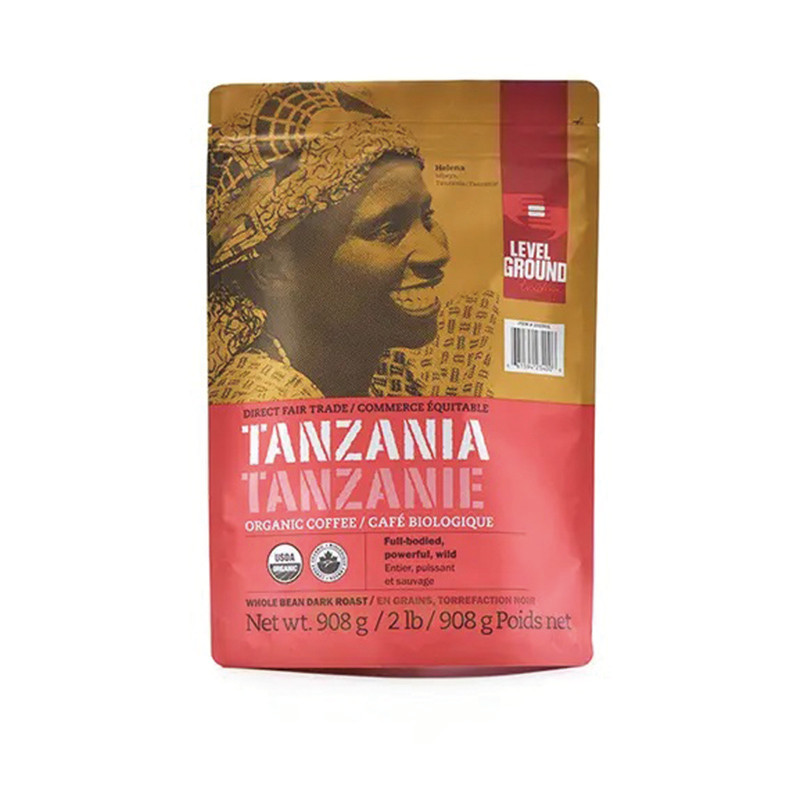

Customized Kraft paper flat bottom Pouch for Coffee beans and food packaging

Product Detail

Kraft paper bags come in various styles, each designed for specific functions, capacities, and aesthetic appeals. Here are the primary types:

1. Side Gusset Bags

These bags have pleated sides (gussets) that allow the bag to expand outward, creating a larger capacity without increasing the bag's height. They often have flat bottoms for stability.

Best For: Packaging thicker items like clothing, books, boxes, and multiple items. Popular in fashion retail.

2. Flat Bottom Bags (with Block Bottom)

This is a more robust version of the side gusset bag. Also known as a "block bottom" or "automatic bottom" bag, it has a sturdy, square flat base that is mechanically locked in place, allowing the bag to stand upright on its own. It offers a very high weight capacity.

Best For: Heavy items, premium retail packaging, wine bottles, gourmet foods, and gifts where a stable, presentable base is important.

3. Pinch Bottom Bags (Open Mouth Bags)

Typically used for heavier-duty applications, these bags have a large open top and a pinched bottom seam. They are often used without handles and are designed for filling and transporting bulk materials.

Best For: Industrial and agricultural products like animal feed, fertilizer, charcoal, and construction materials.

4. Pastry Bags (or Bakery Bags)

These are simple, lightweight bags without handles. They often have a flat or folded bottom and are sometimes equipped with a clear window to display the baked good inside.

Best For: Bakeries, cafes, and take-out food items like pastries, cookies, and bread.

5. Stand Up Pouches (Doypack Style)

While not a traditional "bag," stand-up pouches are a modern, flexible packaging option made from laminated kraft paper and other materials. They feature a gusseted bottom that allows them to stand upright on shelves like a bottle. They always include a resealable zipper.

Best For: Food products (coffee, snacks, grains), pet food, cosmetics, and liquids. Ideal for products that need shelf presence and freshness.

6. Shaped Bags

These are custom-designed bags that deviate from standard shapes. They can have unique handles, asymmetrical cuts, special die-cut windows, or intricate folds to create a specific look or function.

Best For: High-end luxury branding, special promotional events, and products that require a unique, memorable unboxing experience.

The choice of bag depends on your product's weight, size, and the brand image you wish to project. Flat bottom and side gusset bags are the workhorses of retail, while stand-up pouches are excellent for shelf-stable goods, and shaped bags are for making a bold branding statement.

Detailed introduction to the suggested material structures for kraft paper bags, explaining their composition, benefits, and typical applications.

These combinations are all laminates, where multiple layers are bonded together to create a material that outperforms any single layer alone. They combine the natural strength and eco-friendly image of kraft paper with the functional barriers of plastics and metals.

1. Kraft Paper / Coated PE (Polyethylene)

Key Features:

Moisture Resistance: The PE layer provides an excellent barrier against water and humidity.

Heat Sealability: Allows the bag to be sealed shut for freshness and safety.

Good Durability: Adds tear resistance and flexibility.

Cost-Effective: The simplest and most economical barrier option.

Ideal For: Standard retail bags, takeaway food bags, non-greasy snack packaging, and general-purpose packaging where a basic moisture barrier is sufficient.

2. Kraft Paper / PET / AL / PE

A multi-layer laminate consisting of:

Kraft Paper: Provides structure and the natural aesthetic.

PET (Polyethylene Terephthalate): Provides high tensile strength, puncture resistance, and stiffness.

AL (Aluminum): Provides a complete barrier to light, oxygen, moisture, and aromas. This is critical for long-term preservation.

PE (Polyethylene): The innermost layer, provides heat sealability.

Key Features:

Exceptional Barrier: The aluminum layer makes this the gold standard for protection, extending shelf life significantly.

High Strength: The PET layer adds tremendous durability and puncture resistance.

Lightweight: Despite its strength, it remains relatively light.

Ideal For: Premium coffee beans, sensitive spices, nutritional powders, high-value snacks, and products that require absolute protection from light and oxygen (photodegradation).

3. Kraft Paper / VMPET / PE

Key Features:

Excellent Barrier: Provides very high resistance to oxygen, moisture, and light, but may have minor microscopic pores.

Flexibility: Less prone to cracking and flex fatigue compared to solid AL foil.

Cost-Effective Barrier: Offers most of the benefits of aluminum foil at a lower cost and with greater flexibility.

Aesthetic: Has a distinctive metallic sparkle instead of a flat aluminum look.

Ideal For: High-quality coffee, gourmet snacks, pet food, and products that need strong barrier properties without the highest premium cost. Also used for bags where a shiny interior is desired.

4. PET / Kraft Paper / VMPET / PE

Key Features:

Superior Print Durability: The outer PET layer acts as a built-in protective overlaminate, making the bag's graphics highly resistant to scratching, rubbing, and moisture.

Premium Feel & Look: Creates a glossy, high-end surface.

Enhanced Toughness: The outer PET film adds significant puncture and tear resistance.

Ideal For: Luxury retail packaging, high-end gift bags, premium product packaging where the bag's appearance must remain flawless throughout the supply chain and customer use.

5. Kraft Paper / PET / CPP

Key Features:

Excellent Heat Resistance: CPP has a higher heat tolerance than PE, making it suitable for hot filling applications.

Good Clarity & Gloss: CPP is often clearer and glossier than PE, which can enhance the appearance of the bag's interior.

Stiffness: Provides a crisper, more rigid feel compared to PE.

Ideal For: Packaging that may involve warm products, certain types of medical packaging, or applications where a stiffer, more rigid bag feel is desired.

| Summary Table | ||

| Material Structure | Key Feature | Primary Use Case |

| Kraft Paper / PE | Basic Moisture Barrier | Retail, Takeaway, General Use |

| Kraft Paper / PET / AL / PE | Absolute Barrier (Light, O₂, Moisture) | Premium Coffee, Sensitive Foods |

| Kraft Paper / VMPET / PE | High Barrier, Flexible, Metallic Look | Coffee, Snacks, Pet Food |

| PET / Kraft Paper / VMPET / PE | Scuff-Resistant Print, Premium Look | Luxury Retail, High-End Gifts |

| Kraft Paper / PET / CPP | Heat Resistance, Rigid Feel | Warm Fill Products, Medical |

How to Choose the best kraft paper bags for my products:

The best material depends on your product's specific needs:

1. Does it need to stay crisp? -> A moisture barrier (PE) is essential.

2. Is it oily or greasy? -> A good barrier (VMPET or AL) prevents staining.

3. Does it spoil from light or air? -> A full barrier (AL or VMPET) is required.

4. Is it a premium product? -> Consider an outer PET layer for protection or VMPET for a luxury feel.

5. What is your budget? -> Simpler structures (Kraft/PE) are more cost-effective.