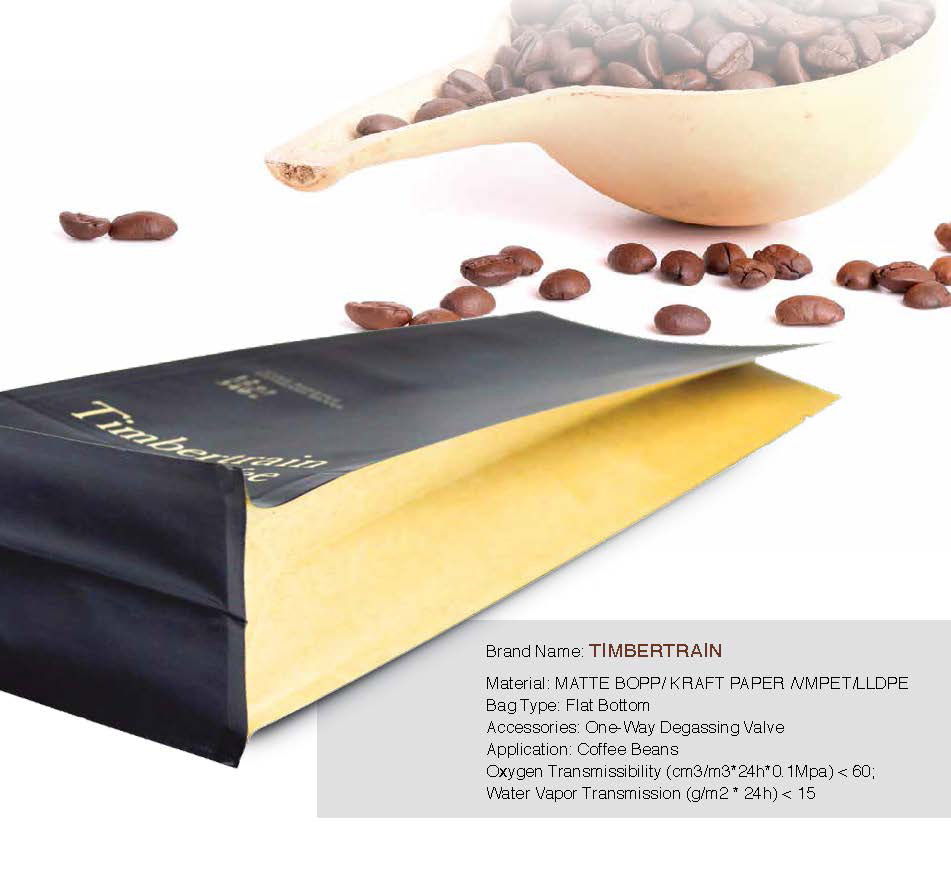

Customized Food grade Flat Bottom Pouch With Valve for Coffee Packaging

Product Detail

250g,500g,1000g manufacturer customized flat bottom pouch with zipper and valve for coffee bean packaging.

OEM &ODM manufacturer for coffee bean packaging, with BRC FDA and food grades certificates reach international standards .

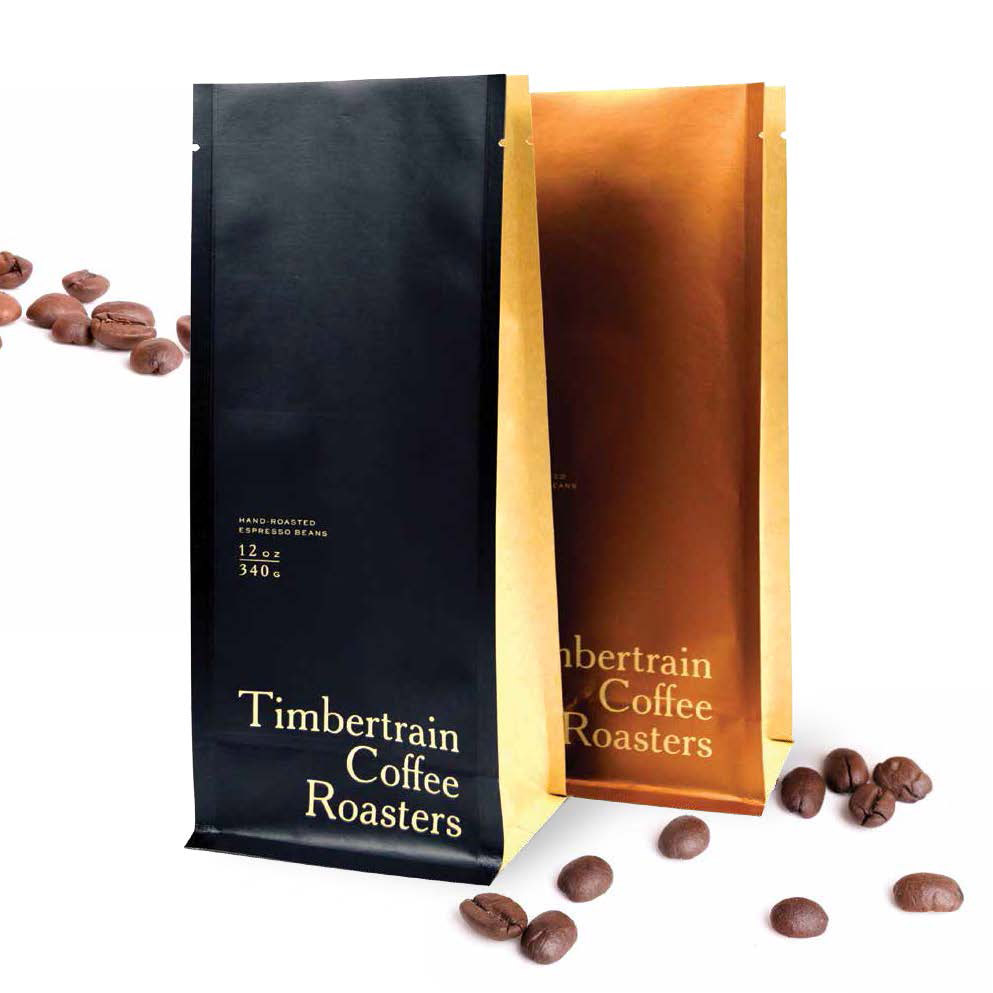

Flat bottom pouches are the new favorite kind of bags in flexible packaging field. It is fast increasing in high-end food packaging industry. Flat bottom pouches are more costing than others of flexible packaging bags. But based on pouch shape and more convenience, which becomes more and more popular in packaging industry, however flat bottom pouches with a variety of names, for example block bottom bags, flat bottom bags, square bottom bags, box bottom bags, quad seal bottom pouches, quad seal bottom bags, brick bags, four side sealed flat bottom, three-side buckle bags. The flat bottom pouches look like a brick or box style, With five surfaces, front side, back side, right side gusset, left side gusset, and bottom side, which also can be printed with their design. Showing their products and brands. Due to its unique design, flat bottom bags can save 15% of packaging materials.Since the flat-bottomed bags stand tall and the width of the bags is narrower than the stand-up bags. More food manufacturers choose to use flat bottom pouches, this type of bag can save the cost of supermarket shelf space. Which also called environmental protection packaging bag.

| Item: | High Quality Flat Bottom Food Packaging Pouch for Coffee Beans |

| Material: | Laminated material , PET/VMPET/PE |

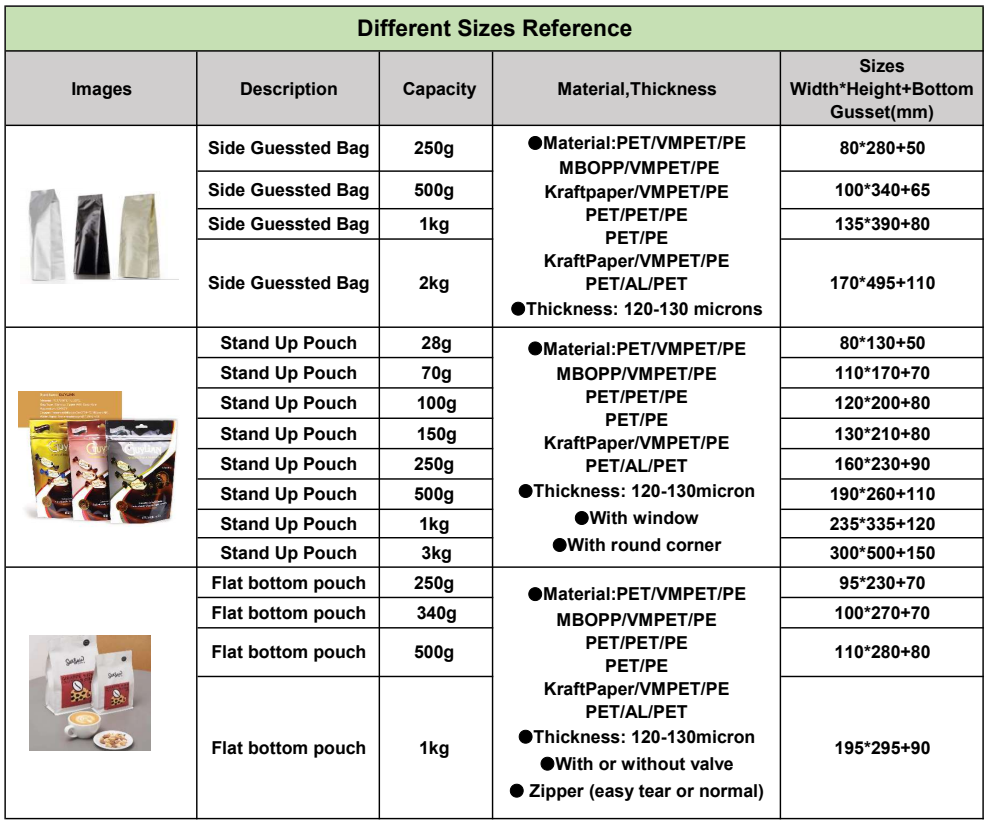

| Size & Thickness: | Customized according to customer’s requirements. |

| Color /printing: | Up to 10 colors , using food grade inks |

| Sample: | Free Stock Samples provided |

| MOQ: | 5000pcs - 10,000pcs based on bag size and design. |

| Leading time: | within 10-25 days after order confirmed and receiving 30% deposit. |

| Payment term: | T/T(30%deposit, the balance before delivery; L/C at sight |

| Accessories | Zipper/Tin Tie/Valve/Hang Hole/Tear notch / Matt or Glossy etc |

| Certificates: | BRC FSSC22000,SGS ,Food Grade. certificates can also be made if necessary |

| Artwork Format: | AI .PDF. CDR. PSD |

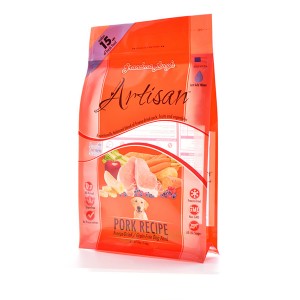

| Bag type/Accessories | Bag Type:flat bottom bag, stand up bag, 3-side sealed bag, zipper bag, pillow bag, side/bottom gusset bag, spout bag, aluminum foil bag, kraft paper bag, irregular shape bag etc.Accessories:Heavy duty zippers, tear notches, hang holes, pour spouts, and gas release valves, rounded corners, knocked out window providing a sneak peak of what inside :clear window, frosted window or matt finish with glossy window clear window, die – cut shapes etc. |

Any query, Please be free to contact us directly.

FAQ for Rearch&Design

Q1:How are your products made up? What are the specific materials?

Normally Pouches made with three layers, The exterior of flexible packaging pouches is made of Opp ,Pet, Paper and Nylon, The middle layer with Al, Vmpet, Nylon, and the inner layer with PE, CPP

Q2:How long does it take for your company's printing mold development?

The development of new molds should be based on the product to determine the time period, in the case of little change in the original product, 7-15 days can be satisfied.

Q3:Does your company charge printing mold fees? how many? Can it be returned? How to return it?

The number of newly developed products printing mold fee is $50-$100 per printing mould

If there is not such a large quantity in the early stage, you can charge the mold fee first and return it later. The return is determined according to the quantity to be returned in batches.