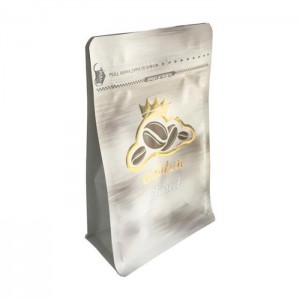

Customized Stand Up Pouch With Hot Foil Stamping

What is hot stamp printing?

Hot stamping foil is a thin film used to permanently transfer aluminium or pigmented colour designs to a substrate via a stamping process. Heat and pressure is applied to the foil over a substrate using a stamping die (plate) in order to melt the adhesive layer of the foil to permanently transfer to the substrate. Hot stamping foil, although thin itself, is made up of 3 layers; a waste carrier layer, the metallic aluminium or pigmented colour layer and finally the adhesive layer.

Bronzing is a special printing process that does not use ink. The so-called hot stamping refers to the process of hot stamping anodized aluminum foil onto the surface of the substrate under a certain temperature and pressure.

With the development of the printing and packaging industry, people require product packaging: high-end, exquisite, environmentally friendly and personalized. Therefore, the hot stamping process is loved by people because of its unique surface finishing effect, and it is used in high-end packaging such as banknotes, cigarette labels, medicines, and cosmetics.

The hot stamping industry can be roughly divided into paper hot stamping and plastic hot stamping.

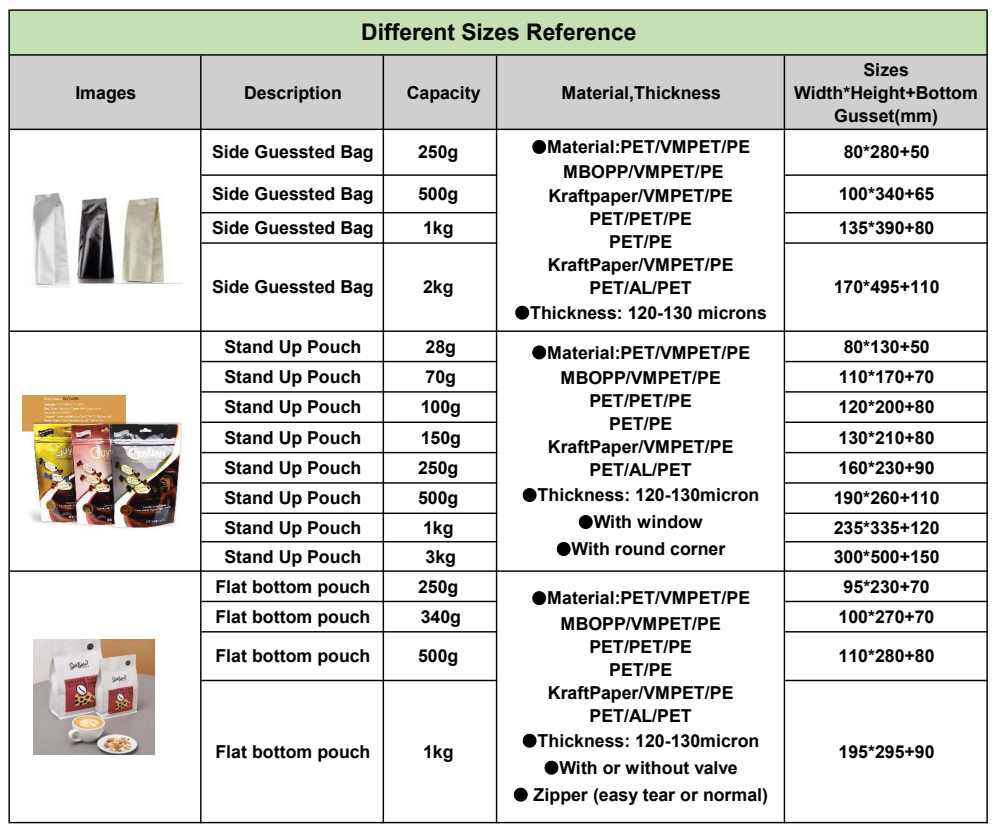

Quick Goods Detail

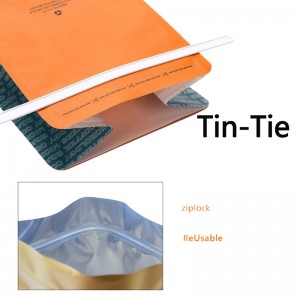

| Bag Style: | Stand up pouch | Material Lamination: | PET/AL/PE, PET/AL/PE, Customized |

| Brand : | PACKMIC,OEM &ODM | Industrial Usage: | food packaging etc |

| Place of original | Shanghai, China | Printing: | Gravure Printing |

| Color: | Up to 10 colors | Size/Design/logo: | Customized |

| Feature: | Barrier, Moisture Proof | Sealing &Handle: | Heat sealing |

Product Detail

Customized Stand Up Pouch with hot foil stamping for food packaging, OEM &ODM manufacturer , with food grades certificates food packaging pouches, The stand up pouch, also called doypack, is traditional retail coffee bag.

Hot Stamping Foil is a kind of dry ink , which is often used for printing with hot stamping machines. The hot stamping machine uses a variety of metal molds for special graphics or logo customization. The heat and pressure process are used to release the color of the foil into the substrate product. with metalized oxide powder spraying on the acetate film carrier. which includes 3 layers: an adhesive layer, a color layer, and a final varnish layer.

Using Foil in your packaging bags ,which can provide you with amazing designs and printing effect with a variety of colors and dimension. It can not only be hot on ordinary plastic film, but also on kraft paper,for some special materials, please confirm with our customer service staff in advance if you require bronzing elements, We will provide you with professional and a complete set of packaging solutions. Foil is interesting, but also very elegant. Aluminum foil expands your creativity with new color and texture trays not found in standard printing art. Make your packaging bags more luxurious.

There are three variants of Hot Stamp Foil: Matte, Brilliant and Specialty. The color is also very colorful, you can customize the color to make it more suitable for the original design of your bag.

If you are willing to have your packaging standing out, it is a good solution to use hot stamping, Any query, please be free to contact with us directly.

FAQ for Project

1. Seeing this, is it similar to stamping?

2. Like the stamp, the bronzing version also needs to be engraved with a mirror image of the content, so that it will be correct when it is stamped/stamped on the paper;

3. Too thin and too thin fonts are difficult to engrave on the seal, and the same is true for the bronzing version. The fineness of small characters cannot reach printing;

4. The precision of seal engraving with radish and rubber is different, the same is true for bronzing, and the precision of copper plate engraving and zinc plate corrosion is also different;

5. Different stroke thicknesses and different special papers have different requirements for temperature and anodized aluminum material. Designers don’t need to worry about it. Please give the pot to the printing factory. You only need to know one thing: abnormal details can be resolved through abnormal prices .