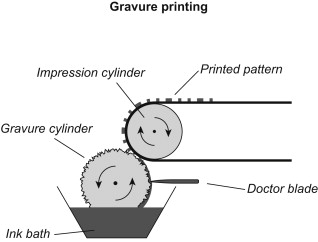

Liquid gravure printing ink dries when one uses a physical method, that is, by evaporation of the solvents, and inks of two components by chemical curing.

What is Gravure Printing

Liquid gravure printing ink dries when one uses a physical method, that is, by evaporation of the solvents, and inks of two components by chemical curing.

What is the advantages and disadvantages of gravure printing.

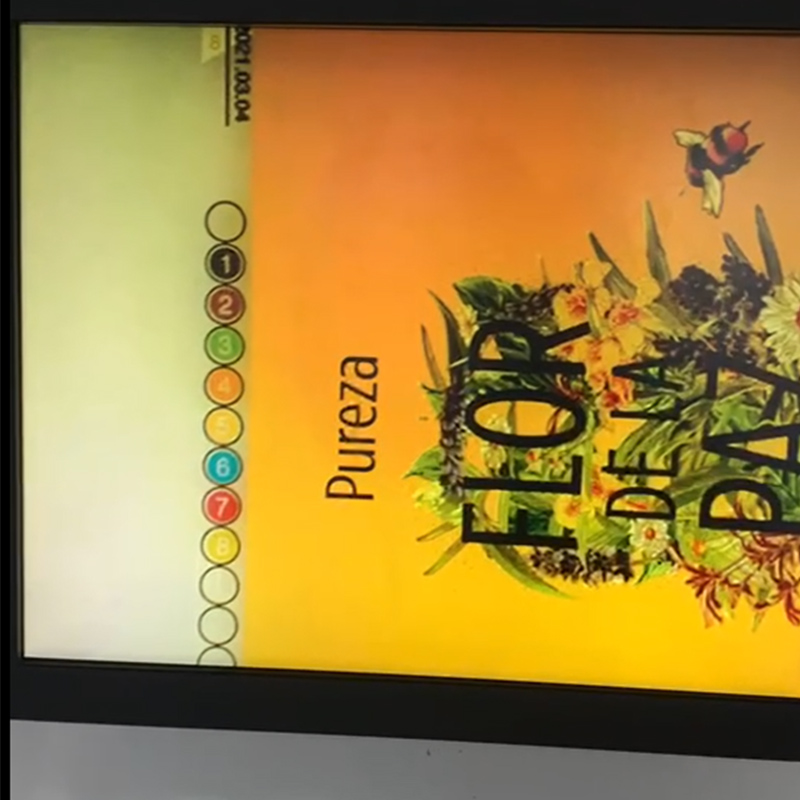

High print quality

The amount of ink used in gravure printing is large, the graphics and text have a convex feeling, and the layers are rich, the lines are clear, and the quality is high. Most of the printing of books, periodicals, pictorials, packaging and decoration is gravure printing

High volume printing

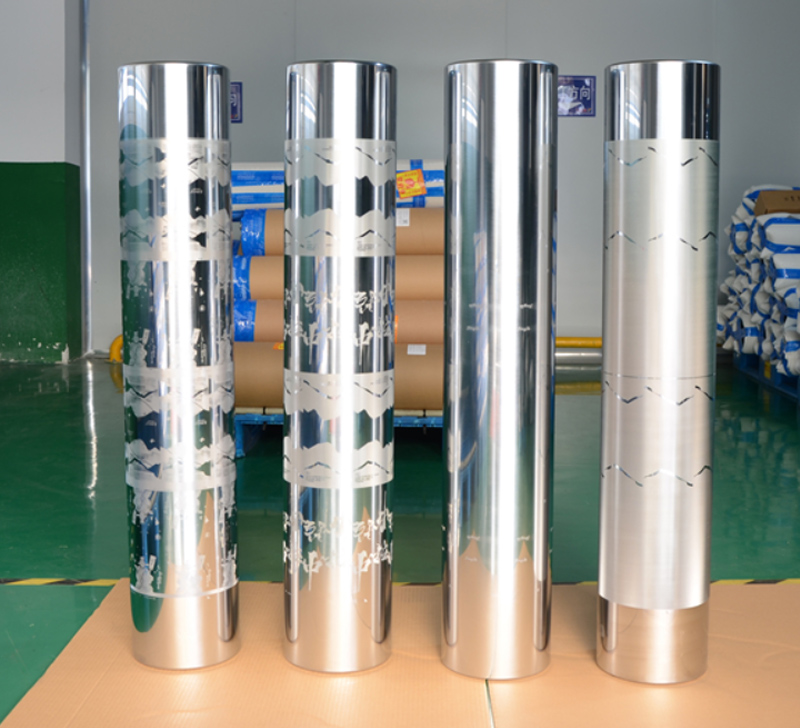

The plate making cycle of gravure printing is long, the efficiency is low, and the cost is high. However, the printing plate is durable, so it is suitable for mass printing. The larger the batch, the higher the benefit, and for printing with a smaller batch, the benefit is lower. Therefore, the gravure method is not suitable for the printing of small batches of trademarks.

(1) Advantages: the ink expression is about 90%, and the color is rich. Strong color reproduction. Strong layout resistance. The number of prints is huge. The application of a wide range of papers, other than paper materials can also be printed.

(2) Disadvantages: plate making costs are expensive, printing costs are also expensive, plate making work is more complicated, and a small number of printed copies are not suitable.

Substrates

Gravure can be used in a wide range of materials, but it is often used to print high-grade paper and plastic film.

Appearance of prints: The layout is clean, uniform, and no obvious dirt marks. Images and text are accurately positioned. The color of the printing plate is basically the same, the size error of fine printing is not more than 0.5mm, the general printing is not more than 1.0mm, and the overprinting error of the front and back sides is not more than 1.0mm

FAQ

Failures in gravure printing are mainly caused by printing plates, inks, substrates, squeegists, etc.

(1) The ink color is light and uneven

Periodic ink color changes occur on printed matter. Elimination methods include: correcting the roundness of the plate roller, adjusting the angle and pressure of the squeegee or replacing it with a new one.

(ii) The imprint is mushy and hairy

The image of the printed matter is graded and pasty, and the edge of the picture and text appears burrs. The methods of elimination are: removing static electricity on the surface of the substrate, adding polar solvents to the ink, appropriately increasing the printing pressure, adjusting the position of the squeegee, etc.

3)The phenomenon that the blocking ink dries up in the mesh cavity of the printing plate, or the mesh cavity of the printing plate is filled with paper hair and paper powder, is called blocking the plate. The methods of elimination are: increasing the content of solvents in the ink, reducing the speed of ink drying, and printing with paper with high surface strength.

4) Ink spillage and spotting on the field part of the printed matter. The methods of elimination are: adding hard ink oil to improve the viscosity of the ink. Adjust the angle of the squeegee, increase the printing speed, replace the deep mesh printing plate with a shallow mesh printing plate, etc.

5) Scratch marks: Traces of squeegee on printed matter. Elimination methods include printing with clean inks without foreign matter ingress. Adjust the viscosity, dryness, adhesion of ink. Use a high-quality squeegee to adjust the angle between the squeegee and the plate.

6) Pigment precipitation

The phenomenon of lightening the color on the print. The methods of elimination are: printing with inks with good dispersion and stable performance. Anti-agglomeration and anti-precipitation additives are added to the ink. Roll well and stir the ink in the ink tank frequently.

(7)The phenomenon of ink stains on sticky printed matter. The methods of elimination are: select ink printing with fast volatilization speed, increase the drying temperature or appropriately reduce the printing speed.

(8) Ink shedding

The ink printed on the plastic film has poor adhesion and is rubbed off by hand or mechanical force. The methods of elimination are: prevent the plastic film from moisture, choose ink printing with good affinity with the plastic film, re-surface the plastic film, and improve the surface tension

Development trends

Due to environmental protection and health reasons, food, medicine, tobacco, alcohol and other industries pay more and more attention to the environmental protection of packaging materials and printing processes, and gravure printing enterprises pay more attention to the environment of printing workshops. Environmentally friendly inks and varnishes will become more and more popular, closed squeegee systems and quick-change devices will be popularized, and gravure presses adapted to water-based inks will be widely used

Post time: May-22-2023