microwave bag

| Size | Custom |

| Type | Stand up Pouch with Zip, Steaming hole |

| Features | Frozen, retorting, boiling, microwavable |

| Material | Custom Sizes |

| Prices | FOB , CIF , DDP , CFR |

| MOQ | 100,000 pcs |

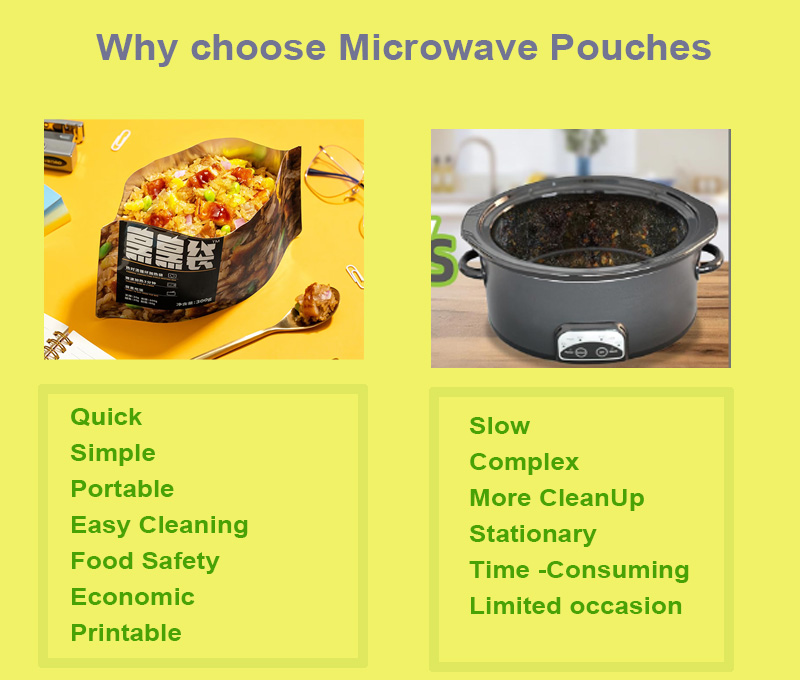

Key Features

Heat Resistance: Made from durable materials (e.g., PET, PP, or nylon layers) that can endure microwave heating and boiling water.

Convenience: Allows consumers to cook or reheat food directly in the pouch without transferring contents.

Seal Integrity: Strong seals prevent leaks and ruptures during heating.

Food Safety: BPA-free and compliant with FDA/EFSA food contact regulations.

Reusability (some types): Certain pouches can be resealed for multiple uses.

Printability: High-quality graphics for branding and cooking instructions

Common Applications

These pouches offer a convenient, time-saving solution for modern consumers while maintaining food quality and safety.

Retort Pouch Material Structure (Microwaveable & Boilable)

Retort pouches are designed to withstand high-temperature sterilization (up to 121°C–135°C) and are also microwaveable and boilable. The material structure consists of multiple layers, each serving a specific function:

Typical 3-Layer or 4-Layer Structure:

Outer Layer (Protective & Printing Surface)

Material: Polyester (PET) or Nylon (PA)

Function: Provides durability, puncture resistance, and a printable surface for branding.

Middle Layer (Barrier Layer – Prevents Oxygen & Moisture Ingress)

Material: Aluminum foil (Al) or transparent SiO₂/AlOx-coated PET

Function: Blocks oxygen, light, and moisture to extend shelf life (critical for retort processing).

Alternative: For fully microwaveable pouches (no metal), EVOH (ethylene vinyl alcohol) is used as an oxygen barrier.

Inner Layer (Food-Contact & Heat-Sealable Layer)

Material: Cast Polypropylene (CPP) or Polypropylene (PP)

Function: Ensures safe food contact, heat-sealability, and resistance to boiling/retort temperatures.

Common Retort Pouch Material Combinations

| Structure | Layer Composition | Properties |

| Standard Retort (Aluminum Foil Barrier) | PET (12µ) / Al (9µ) / CPP (70µ) | High barrier, opaque, long shelf life |

| Transparent High-Barrier (No Foil, Microwave-Safe) | PET (12µ) / SiO₂-coated PET / CPP (70µ) | Clear, microwaveable, moderate barrier |

| EVOH-Based (Oxygen Barrier, No Metal) | PET (12µ) / Nylon (15µ) / EVOH / CPP (70µ) | Microwave & boil-safe, good oxygen barrier |

| Economy Retort (Thinner Foil) | PET (12µ) / Al (6µ) / CPP (50µ) | Lightweight, cost-effective |

Considerations for Microwaveable & Boilable Pouches

For Microwave Use: Avoid aluminum foil unless using specialized "microwave-safe" foil pouches with controlled heating.

For Boiling: Must withstand 100°C+ temperatures without delamination.

For Retort Sterilization: Must endure high-pressure steam (121°C–135°C) without weakening.

Seal Integrity: Critical to prevent leaks during cooking.

Recommended Retort Pouch Materials for Ready-to-Eat Rice

Ready-to-eat (RTE) rice requires high-temperature sterilization (retort processing) and often microwave reheating, so the pouch must have:

Strong heat resistance (up to 135°C for retort, 100°C+ for boiling)

Excellent oxygen/moisture barrier to prevent spoilage & texture loss

Microwave-safe (unless intended for stovetop-only heating)

Best Material Structures for RTE Rice Pouches

1. Standard Retort Pouch (Long Shelf Life, Non-Microwaveable)

✅ Best for: Shelf-stable rice (6+ months storage)

✅ Structure: PET (12µm) / Aluminum Foil (9µm) / CPP (70µm)

Pros:

Superior barrier (blocks oxygen, light, moisture)

Strong seal integrity for retort processing

Cons:

Not microwave-safe (aluminum blocks microwaves)

Opaque (can’t see product inside)

Transparent High-Barrier Retort Pouch (Microwave-Safe, Shorter Shelf Life)

✅ Best for: Premium RTE rice (visible product, microwave reheating)

✅ Structure: PET (12µm) / SiO₂ or AlOx-coated PET / CPP (70µm)

Pros:

Microwave-safe (no metal layer)

Transparent (enhances product visibility)

Cons:

Slightly lower barrier than aluminum (shelf life ~3–6 months)

More expensive than foil-based pouches

EVOH-Based Retort Pouch (Microwave & Boil-Safe, Medium Barrier)

✅ Best for: Organic/health-focused RTE rice (no foil, eco-friendly option)

✅ Structure: PET (12µm) / Nylon (15µm) / EVOH / CPP (70µm)

Pros:

Foil-free & microwave-safe

Good oxygen barrier (better than SiO₂ but less than Al foil)

Cons:

Higher cost than standard retort

Requires additional drying agents for very long shelf life

Additional Features for RTE Rice Pouches

Easy-peel resealable zippers (for multi-serve packs)

Steam vents (for microwave reheating to prevent bursting)

Matte finish (prevents scuffing during shipping)

Clear bottom window (for product visibility in transparent pouches)